- 网站导航 -

Address:Home > Products > Flexible welding platform >

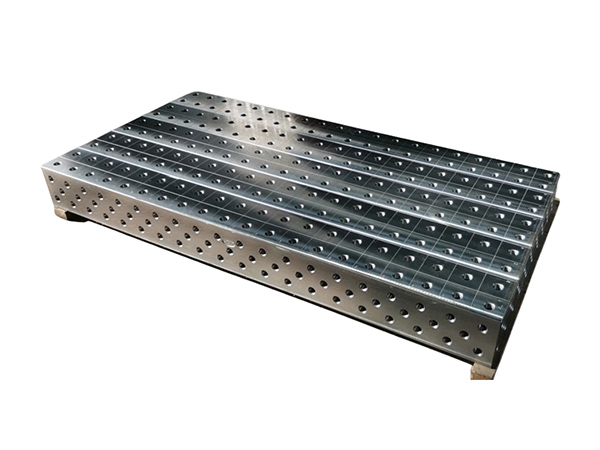

Three-dimensional flexible combined tooling platform

E-mail: info@measuringtools-factory.com

Three-dimensional flexible combined tooling platform material: casting (HT300), which is subjected to overall annealing heat treatment to eliminate internal stress and then left for three to six months for natural aging treatment.

The five working surfaces of the three-dimensional flexible welding workbench work surface have holes with grid markings of 100x100 mm or 50x50mm. The plane, parallel, and vertical tolerance accuracy of its five surfaces and the position accuracy of holes are very high. The positioning of the protection on the table and the combination between the table and other modules have sufficient accuracy requirements. The size of the basic countertop can be selected from 1000x1000mm to 4000x2000mm, and special sizes can be customized.

Four major characteristics of the three-dimensional flexible combined tooling platform:

1. Economical: The cost and time invested in tooling for each product change can almost no longer be spent. The device is easy to operate and safe to use. Users can assemble work clothes with different requirements at the appropriate speed according to their needs, just like children playing with assembly toys.

2. Flexibility: high load-bearing capacity and stable rigidity. Its five sides are processed with regular holes and engraved with network cables. The welding platform can be easily extended and expanded, combined. The extended standard table tops can be modularly positioned and clamped directly together. The universal functions of the flexible three-dimensional combined welding tooling system are demonstrated with excellent quality in the process of installing, adjusting and positioning the workpiece, especially in the application of large workpieces.

There are various assembly methods. As long as the user gives full play to their imagination, they can achieve almost the same positioning and clamping functions of any clamp. The assembly speed is suitable and the assembly and disassembly are convenient; the work surface can be assembled and combined according to the shape and size of the workpiece. The scale on the table and the design of the module size allow the operator to quickly and appropriately set up the required tooling according to the size of the workpiece without using measuring tools.

3. Accuracy: Under the action of a concentrated load of about 2 tons and 1M2, the deformation does not exceed 0.50mm, and under the action of a uniform load, the deformation is only 0.024mm, which can meet the needs of most welding and assembly processes. The accuracy of its assembly is good, and the center tolerance of the positioning hole of the working platform is within 0.05mm. This appropriate accuracy will be reflected in the products processed by the user, so this workbench can also be used as a reference platform for inspection tools.

4. Repeatability: The tabletop is composed of cast iron/steel structure parts/meticulously machined parts/modular components. Its performance is very stable. If parts are damaged due to improper use, there is no need to scrap the entire table, and it only costs very little. Individual parts can be replaced. The welding platform has been specially processed. During the welding process, low-cost anti-spatter fluid is needed to avoid welding spatter on the surface of the workbench.

Issues to note when designing a three-dimensional flexible combined tooling platform:

1. After welding, the workpiece cannot be taken out. This is also caused by shrinkage and deformation during welding, so the method of removing the mold must be reasonably arranged.

2. After welding, the size is wrong, because most shrinkage deformation occurs during welding, and a suitable margin needs to be left in the direction of shrinkage.

3. After welding, it is still very open and needs to be processed again. This is a lack of rigidity in the clamp design. The work clothes themselves have been deformed.

4. If you know that the deformation cannot be overcome by the tooling itself, you should consider using anti-deformation methods to arrange the shaping and positioning of the tooling fixture.