- 网站导航 -

Address:Home > Products > Flexible welding platform >

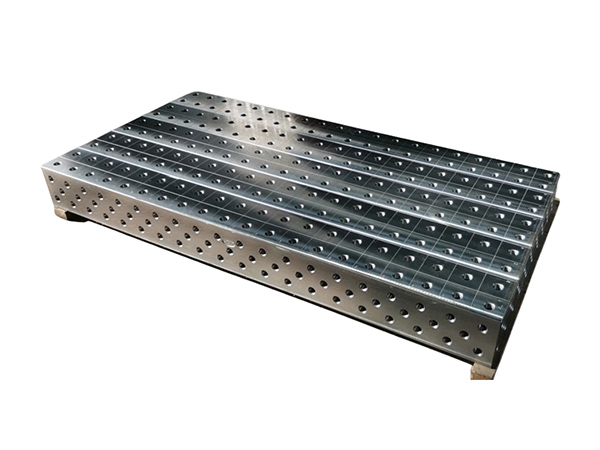

Three-dimensional flexible welding tooling platform

E-mail: info@measuringtools-factory.com

The three-dimensional flexible welding tooling platform is a workbench used for welding large wall panel parts on aircraft. It is used to support and compress the parts. It solves the problem of manual lifting and lowering of the previous welding workbench, high labor intensity for the operator, low lifting and moving efficiency and low accuracy. Low, long preparation time, low workbench efficiency and other shortcomings.

Three-dimensional flexible welding tooling platform consists of:

1. Work surface

Each of the five working surfaces of the workbench has 100mm × 100mm (D28 series) or 50mm × 50mm (D16 series) holes with grid markings. The plane, parallel and vertical tolerance accuracy of its five surfaces as well as the position accuracy of holes and holes are very high. There are sufficient accuracy requirements for use on the tabletop and the combination between the tabletop and other modules. The size of the basic countertop can be selected from 1000mm×1000mm to 4000mm×2000mm, and the size can be customized. If the precision requirements for the combination of tabletops and tabletops are high, guide rails can be used to connect them.

2. Module

Standard modules include: clamping right-angle block, L-shaped block, U-shaped block, universal stop block, universal clamping and angle die (0~225° adjustable), V-shaped block and V-shaped angle die. All modules have standard holes (Φ28 or Φ16) every 50mm or 25mm, which can realize workpiece and clamping.

3. Connecting pin

This is the basic part to implement the hole system clamping system to achieve and clamping. There are 5 steel balls at the front end of the pin. Manually rotate the pin clockwise (or pull the handle), and the 5 steel balls will pop out and lock on the slope of the hole to complete and clamp; when loosened, rotate the pin in the opposite direction, that is, Can be pulled out. Each pin has a locking force of up to 5t and a shearing force of 25t. Dowels are available in a variety of shapes and lengths.

4. Clamp

According to the clamping direction, there are plane, vertical and 45° clamps; according to the operation mode, there are bolt clamping, clamping and handle spiral clamping. In addition, there are three clamping methods: manual, pneumatic or hydraulic. Among them, the spiral clamp with compensation is commonly used. This kind of clamp adds elastic expansion and contraction in the cantilever to offset the lateral component force during clamping to compensate for the deformation of the clamp itself and the gap during the insertion process. The tightening force is perpendicular to the stress surface. The clamping head is made of carbon steel, stainless steel, and nylon materials to suit different workpiece requirements. There are also two-point clamping bridges that can clamp workpieces at two positions at different heights at the same time. In addition, the clamping head can also be processed according to the clamping profile.