- 网站导航 -

Address:Home > Products > Flexible welding platform >

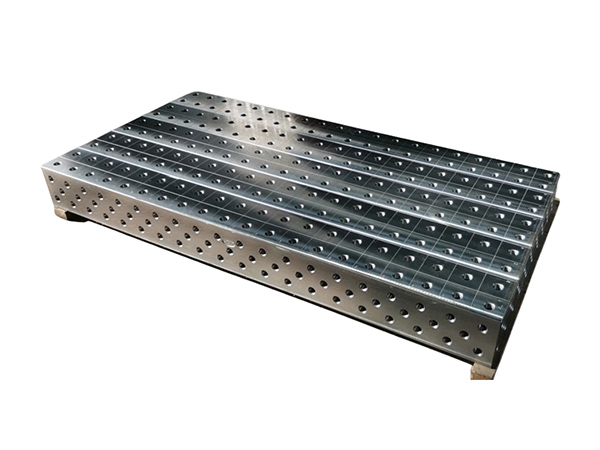

Features of two-dimensional flexible welding platform

1. The design and production precision is high; it can effectively ensure the size of the welded product; the welding, heat treatment, rough machining and semi-finishing of the blank are all subject to quality process control; especially the finishing process is completed with one-time clamping and CNC gantry milling machine. Ensure the hole position accuracy of the platform

2. High repeat positioning accuracy; different products can be accurately positioned modularly on one basic part. By forming a positioning module using a universal basic board, each product can be positioned repeatedly; when changing models/converting production, the accuracy of the product and the efficiency of production conversion can still be ensured.

3. The platform and accessories can be extended; it can adapt to changes in different product specifications, improving the utilization rate of tooling; the weldability of welding products is destined to have variable and irregular shapes and structures

4. The product can be quickly clamped, positioned and disassembled during welding; improving production efficiency;

5. Reusable; directly reduces costs

6. Maintenance is simple, only need to use surface protection; reduce the maintenance content of tooling, reduce labor intensity and maintenance costs of workers

7. Easy to disassemble and assemble, easy to store and manage; no special fixture warehouse is required, reducing warehouse management and maintenance costs.

8. It is easy to operate and does not require professional technicians to operate. It can be used by general operating employees; it will not increase labor costs.

Two-dimensional flexible platform repair and maintenance

Sturdy and durable During the welding process, only low-cost anti-spatter fluid is needed to eliminate welding spatter on the surface of the 3D workbench. The workbench has undergone aging treatment and special processing. Through modular design and interchangeability, you can complete complex and precise tooling combinations in a short time. This method is very economical whether making a single part or assembling an assembly. The gridded high-precision holes on the table and each module enable clamping to achieve high accuracy and repeatability.