- 网站导航 -

Address: Home > News > Technical documentation >

Design and Implementation of Flexible Welding Platforms: Key to Enhancing Manufacturing Flexibility

Time:2024-08-23 05:39:34 Author:Fadetong Clicks:88Second-rate

Introduction

Flexible welding platforms are becoming essential tools in modern manufacturing, especially in environments requiring high precision and adaptability. Through advanced design and technology, these platforms not only optimize production processes but also enhance welding quality. This article will delve into the design principles and implementation methods of flexible welding platforms, showcasing how these platforms can boost manufacturing flexibility and efficiency.

1. Design Principles of Flexible Welding Platforms

1.1. Modular Design

Modular design is a core principle of flexible welding platforms. By breaking the platform into independent modules, it allows for flexible configuration based on different welding needs. This design enhances adaptability and simplifies maintenance and upgrades. Modular platforms enable manufacturers to quickly adjust production lines to meet changing market demands and product specifications. If your production environment requires flexible adjustments, a modular flexible welding platform is ideal.

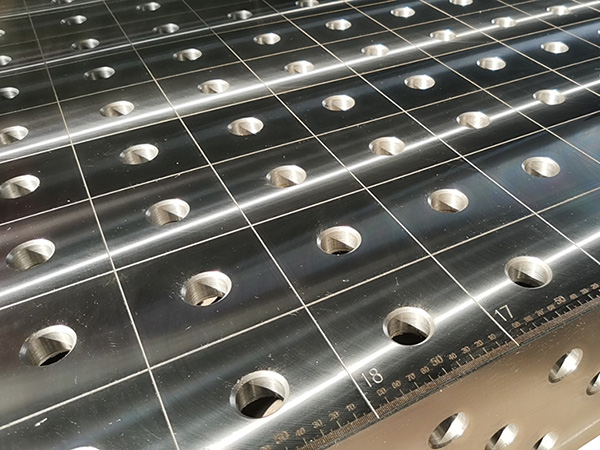

1.2. High-Precision Positioning

High-precision positioning is crucial for ensuring welding quality. Flexible welding platforms should be equipped with advanced positioning systems to ensure accurate alignment of welding components. Precise positioning reduces welding defects and enhances both weld strength and appearance. Choosing a platform with high-precision positioning features will help you achieve superior welding connections.

1.3. User-Friendly Interface

To improve operational efficiency, flexible welding platforms need user-friendly interfaces. These interfaces should offer intuitive control and monitoring functions, simplifying the operational process. An easy-to-use interface allows operators to quickly master the system, reducing training time and operational errors. If you seek to enhance operational convenience, a user-friendly interface will greatly optimize your production process.

1.4. Durability and Stability

The durability and stability of a flexible welding platform directly impact its long-term effectiveness. The platform should be constructed from high-quality materials and robust design to withstand prolonged use and high-load operations. Ensuring the platform remains stable and reliable under various working conditions will minimize failure rates and maintenance costs. If long-term stability and lifespan are priorities, selecting a durable flexible welding platform is essential.

2. Implementation Methods for Flexible Welding Platforms

2.1. Integration of Advanced Technologies

Implementing flexible welding platforms requires the integration of advanced technologies, including automation control systems, sensors, and data analysis tools. Automation systems enable precise welding parameter adjustments, sensors provide real-time monitoring data, and data analysis tools help optimize welding processes. By integrating these technologies, flexible welding platforms offer efficient and reliable welding solutions. If you want comprehensive technology integration, choosing a platform with these features is a wise decision.

2.2. Customized Solutions

To meet diverse customer needs, flexible welding platforms often require customized designs. Tailored solutions based on specific production requirements and product specifications can include platform size, welding functions, and automation levels. Customized platforms better adapt to particular production environments and needs, achieving optimal production outcomes. If your production requirements are unique, a customized flexible welding platform will provide precise solutions.

2.3. Testing and Optimization

Testing and optimization are crucial steps in the implementation of flexible welding platforms. Comprehensive testing identifies potential issues and allows for optimization, ensuring system stability and performance. The optimization process involves adjusting welding parameters, improving control algorithms, and refining the user interface. Regular testing and optimization will ensure your flexible welding platform performs at its best in actual production.

2.4. Technical Support and Training

Effective implementation of flexible welding platforms also requires comprehensive technical support and training services. Technical support includes system installation, debugging, and troubleshooting, while training helps operators master the platform’s use and maintenance. Providing professional technical support and training ensures the efficient operation and continuous improvement of the platform.

3. Advantages of Choosing Flexible Welding Platforms

3.1. Enhanced Production Flexibility

Flexible welding platforms can be quickly adjusted according to production needs, increasing the flexibility and adaptability of production lines. This flexibility allows manufacturers to swiftly respond to market changes and customer demands, gaining a competitive edge.

3.2. Optimized Welding Quality

High-precision flexible welding platforms ensure accurate alignment of welding components, improving weld quality. Reducing defects and rework enhances the reliability and appearance of products.

3.3. Reduced Production Costs

Through automation and efficient operations, flexible welding platforms minimize manual intervention and operational errors, reducing production costs. Increased production efficiency and optimized resource use lead to cost savings.

3.4. Achievement of Environmental Goals

Modern flexible welding platforms have also made strides in environmental impact. By optimizing welding processes and reducing emissions, they meet environmental standards. Choosing an eco-friendly welding platform supports your company’s sustainable development goals.

Conclusion

Flexible welding platforms play a key role in modern manufacturing by offering modular design, high-precision positioning, user-friendly interfaces, and durability. While implementing these platforms involves integrating advanced technologies, providing customized solutions, conducting testing and optimization, and offering technical support and training, the benefits are substantial. By leveraging flexible welding platforms, you can enhance manufacturing flexibility and efficiency. Contact us today to learn how to incorporate flexible welding platforms into your production line and start your journey towards manufacturing innovation!