- 网站导航 -

Address: Home > News > Technical documentation >

The Importance of Welding Fixtures in Automotive Manufacturing: Key to Enhancing Production Efficiency and Quality

Time:2024-09-30 01:09:36 Author:Fadetong Clicks:183Second-rate

In automotive manufacturing, welding is a critical process, and welding fixtures are essential tools for ensuring welding quality and production efficiency. Welding fixtures play an irreplaceable role in automotive production by ensuring the precision and consistency of each weld point, thereby enhancing the overall vehicle quality and durability. This article explores the importance of welding fixtures in automotive manufacturing and provides practical tips to optimize your welding process for superior production outcomes.

What are Welding Fixtures?

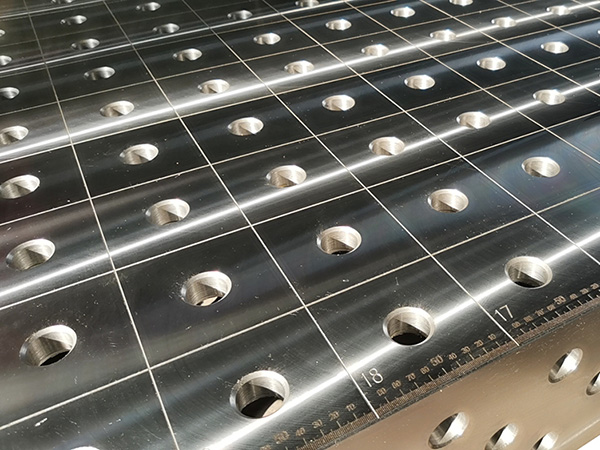

Welding fixtures are tools used to hold and position workpieces, ensuring stability and precision during the welding process. By securely clamping the workpieces in place, welding fixtures prevent deformation or movement during welding, ensuring weld quality and consistency. Welding fixtures are widely used in the production of critical components such as automotive bodies, chassis, and other essential parts.

The Importance of Welding Fixtures in Automotive Manufacturing

1. Improves Welding Precision

Welding fixtures effectively hold workpieces in place, preventing movement or deformation during welding. This is crucial for key components in automotive manufacturing, such as body structures and chassis parts, where precise welding is vital for vehicle safety and durability.

2. Enhances Production Efficiency

Using welding fixtures significantly reduces welding preparation and adjustment time. The standardized design of fixtures allows workpieces to be quickly and accurately secured, greatly improving production efficiency. Additionally, the repeatability of fixtures minimizes human error and adjustment time, ensuring a stable production pace.

3. Ensures Product Consistency

Welding fixtures ensure that each workpiece is consistently positioned and angled during welding, guaranteeing product uniformity. For automotive manufacturing, this means that each vehicle's critical components are welded to the same standard, improving overall product quality and reliability.

4. Reduces Production Costs

By enhancing welding precision and production efficiency, welding fixtures effectively lower production costs. Reducing rework and repairs due to welding defects can significantly save on production costs. Over time, this not only improves the economic efficiency of the production line but also enhances overall profit margins.

How to Choose the Right Welding Fixtures

1. Consider the Shape and Size of the Workpiece

When selecting welding fixtures, choose those that can accurately hold various shapes and sizes of workpieces, meeting the diverse needs of your production line.

2. Opt for High-Quality Materials

High-quality materials for welding fixtures provide better durability and stability, reducing wear and deformation during use. Common materials include steel and aluminum alloys, known for their strength and durability.

3. Custom Design

For specialized welding needs, consider custom-designed fixtures. Custom fixtures perfectly match your production requirements, enhancing the flexibility and adaptability of your welding process.

Why Choose Our Welding Fixture Solutions?

We are dedicated to providing high-quality welding fixture solutions for the automotive manufacturing industry. Our products offer the following advantages:

Precision Design: Our welding fixtures are precisely designed to ensure stability and accuracy for each workpiece during welding.

Superior Materials: Made from high-quality materials, our fixtures provide exceptional durability and long-term stability.

Custom Services: We offer custom design services based on specific customer needs, catering to various welding process requirements.

Expert Support: Our experienced team provides comprehensive technical support and after-sales service to ensure optimal performance of your welding fixtures.

Upgrade Your Welding Process Today!

Choose our welding fixture solutions to enhance your automotive manufacturing efficiency and product quality. Our professional team will help you find the most suitable welding fixtures to meet your production needs.

Contact us today for more information and expert advice on welding fixtures. Let us assist you in optimizing your welding process for outstanding production results.

For more expert advice and high-quality products on welding fixtures, please contact us now! We look forward to working with you to drive innovation and development in the automotive manufacturing industry.