- 网站导航 -

Address: Home > News > Technical documentation >

Comparison Between Flexible Welding Tables and Traditional Welding Stations: Which Is Better for Your Workshop?

Time:2024-10-12 02:42:28 Author:Fadetong Clicks:146Second-rate

In modern manufacturing, welding plays a crucial role in production processes. Choosing the right welding workstation can significantly enhance production efficiency, reduce costs, and improve product quality. As technology advances, flexible welding tables are increasingly competing with traditional welding stations. This article compares these two types of welding equipment, helping you make an informed decision about which is best for your workshop.

What is a Flexible Welding Table?

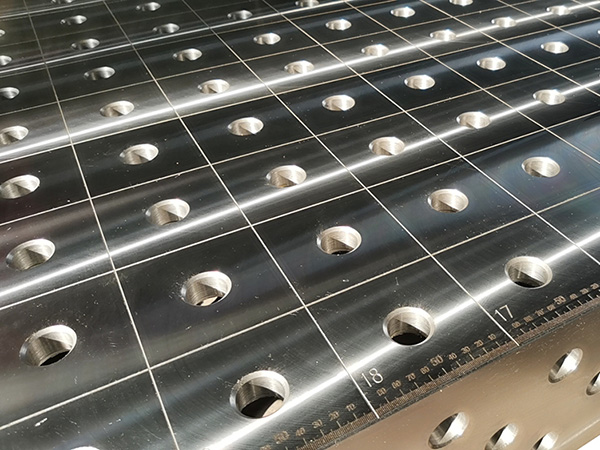

A flexible welding table is designed to be adjustable based on various welding needs. It features a modular design, allowing users to configure the table layout and fixture settings according to the dimensions, shapes, and welding requirements of different workpieces. This design provides high flexibility, making it suitable for multi-variety, small-batch production needs.

Characteristics of Traditional Welding Stations

Traditional welding stations are typically fixed workbenches designed for specific workpieces. They are simple, robust, and durable but lack flexibility and adjustability. Such stations are ideal for high-volume, single-type production environments. They may not be practical in situations where frequent workpiece or process changes are required.

Comparison of Flexible Welding Tables and Traditional Welding Stations

1. Flexibility

Flexible Welding Tables: Thanks to their modular design, flexible welding tables can quickly adjust fixtures and table layouts to meet different workpiece needs. This means that regardless of the size or shape of the workpiece, the flexible welding table can adapt and provide stable support and an operational environment.

Traditional Welding Stations: Traditional stations typically have a fixed structure, making it difficult to change or adjust once installed. This design suits large-scale, standardized production but struggles with small-batch or frequently changing workpieces.

Conclusion: If your workshop involves a variety of products or frequent workpiece changes, a flexible welding table offers superior flexibility.

2. Production Efficiency

Flexible Welding Tables: The modular nature and rapid configuration capabilities of flexible welding tables significantly reduce equipment changeover time, enhancing production efficiency. Precise workpiece positioning also improves welding quality, reducing rework and scrap rates.

Traditional Welding Stations: While traditional welding stations are straightforward to install, their limited flexibility can lead to longer downtime and process delays when dealing with new workpieces or production tasks, impacting overall efficiency.

Conclusion: Flexible welding tables excel in production efficiency, especially for multi-tasking and high-demand welding operations.

3. Cost

Flexible Welding Tables: Although the initial investment is higher, flexible welding tables can save costs in the long run due to their modular design. Their adaptability reduces the need for multiple specialized stations, lowering overall equipment costs.

Traditional Welding Stations: While initial costs are lower, the lack of flexibility can lead to additional investments in new equipment or modifications when adapting to new workpieces or processes, increasing long-term costs.

Conclusion: For long-term cost efficiency, flexible welding tables offer better economic advantages.

4. Application Areas

Flexible Welding Tables: Their adaptable design makes them suitable for a wide range of industries, including automotive manufacturing, aerospace, metalworking, and electronics. They are especially beneficial for multi-variety, small-batch production and customized production needs.

Traditional Welding Stations: Best suited for high-volume, standardized production environments, such as large-scale assembly lines, where fixed workpieces and processes are involved.

Conclusion: Flexible welding tables have a broader range of applications and can meet diverse industrial needs.

Which is Better for Your Workshop?

When choosing a welding workstation, consider the specific requirements of your workshop. If your production focuses on high-volume, single-type production with fixed processes, a traditional welding station may be a more economical choice.

However, if your production line involves multiple products, small batches, or frequent adjustments, a flexible welding table is the superior choice. It not only boosts production efficiency but also reduces long-term equipment costs and excels in precision and adaptability.

Why Choose Our Flexible Welding Tables?

As a leading supplier of welding equipment, we specialize in providing high-quality flexible welding tables to meet various industrial needs. Our products feature advanced modular designs and undergo rigorous quality control to ensure durability and efficiency. Whether you require customized solutions or optimization of existing equipment, our expert team can offer the best recommendations and support.

Contact us today to learn more about our flexible welding tables and how they can transform your production environment into a more intelligent, efficient system. Choose our products to gain greater flexibility and competitive advantage for your workshop!