- 网站导航 -

Address: Home > News > Technical documentation >

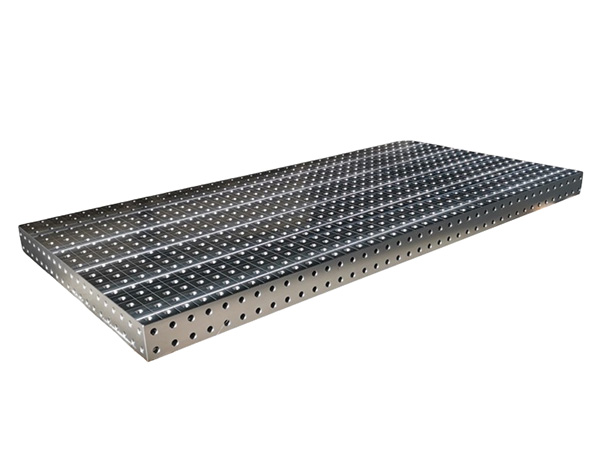

The Application of Flexible Welding Table in Automobile Manufacturing

Time:2024-06-18 10:13:40 Author:Fadetong Clicks:63Second-rate

With the continuous development of the automobile industry, manufacturers are paying more and more attention to the improvement of production efficiency and product quality. In this process, the Flexible Welding Table, as a key component of the automated welding system, is playing an increasingly important role. Let's have an in-depth understanding of the application of the Flexible Welding Table in automobile manufacturing and explore how it becomes a sharp tool to improve the efficiency of automobile production.

1. Improve the flexibility of the production line

The design concept of the Flexible Welding Table aims to achieve diversified welding tasks. In automobile manufacturing, the car body is usually composed of many components with different shapes and sizes, so a flexible welding system is needed to adapt to different welding requirements. Through modular design and multi-axis control system, the Flexible Welding Table can flexibly adapt to the welding processes of different vehicle models and components, thereby improving the flexibility and diversity of the production line.

2. Enhance production efficiency

On the traditional automobile production line, the welding process usually requires a lot of manual intervention, which not only increases the production cost but also limits the room for improvement in production efficiency. While the Flexible Welding Table realizes a high degree of automation in the welding process through the automated control system, greatly reducing the need for manual intervention. The automated welding process can not only improve production efficiency but also reduce the impact of human factors on the welding quality, thereby ensuring the stability and consistency of the welding quality.

3. Ensure the welding quality

In automobile manufacturing, the welding quality directly affects the safety and reliability of the car. And the Flexible Welding Table is equipped with an accurate positioning and control system, which can achieve precise control of the welding position, angle, and trajectory, thereby ensuring the welding quality and consistency. In addition, the Flexible Welding Table is also equipped with various sensors and detectors for real-time monitoring of parameters and conditions during the welding process and realizes the automatic adjustment of welding parameters through the feedback system, thereby further improving the welding quality and stability.

4. Summary

As a key equipment in automobile manufacturing, the application of the Flexible Welding Table not only improves production efficiency but also ensures the welding quality and stability, providing strong support and guarantee for automobile manufacturers. If you are looking for a solution to improve the efficiency of automobile production, the Flexible Welding Table is undoubtedly a choice that you cannot ignore. Welcome to contact us to learn more about the Flexible Welding Table, and we will wholeheartedly provide you with professional consulting and services.