- 网站导航 -

Address:Home > Products > Welding fixture >

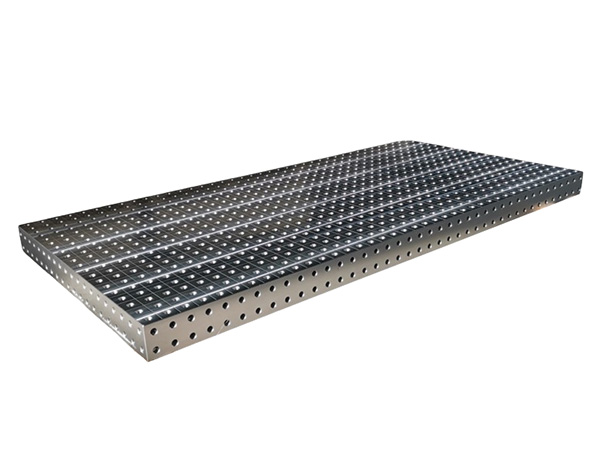

The angle connection block is used for height positioning or platform expansion and positioning or compression of other accessories. It is an element that positions the support on the platform to ensure that the workpiece reaches a certain height requirement during processing.

Specification: 200*200*175, with standard connection holes on the side

Can be used as a three-dimensional expansion transfer component between the platform and the square box

Pipe diameters less than 200 can be used as V-shaped positioning parts

Main functions:

1) 90 degree right angle expansion connection module 2) Pipe fitting workpiece positioning

The device of the angle connecting block includes positioning elements and their combinations. Its function is to determine the position of the workpiece in the fixture, that is, it can make the workpiece in the correct position relative to the tool and the cutting and forming movement during processing, such as support plates, V-shaped blocks, positioning pins, etc.

The angle connection block is used to extend the bevel edge of the fixture table, V-shaped positioning, and as an angle stop for various accessories.

Angle connection block product description

1. Used to connect the four corners or edges of the platform, often used in conjunction with U-shaped square boxes/support angle irons, etc. to achieve platform expansion;

2. There are slots at the bottom, and the position can be adjusted for positioning;

3. It can be used with small accessories to clamp and position the workpiece;

4. The V-shaped 90-degree angle at the top can also be used to position larger pipe fittings;

Angle connection block product maintenance

1. Maintain the workbench at least once a week. Wipe the surface and holes of the workbench clean, and spray anti-rust oil. If it is not used for a long time, keep the platform clean, apply anti-rust oil, and take dust-proof measures.

2. Pay attention to keeping the inside of the system hole clean, clean it regularly with a brush, and apply anti-rust oil. When using the locking pin, there should be no dust or other debris in the hole, otherwise it will easily damage the locking pin and the platform hole, and the locking pin will not be inserted into the hole.

3. After welding is completed, use a whetstone to gently push away the welding slag and other residues on the surface of the platform, and apply anti-rust oil.

Accessories should be maintained regularly, keep the surface clean, and wipe with anti-rust oil.