- 网站导航 -

Address:Home > Products > Welding fixture >

The two-point clamping bridge specification is 175X35X20mm.

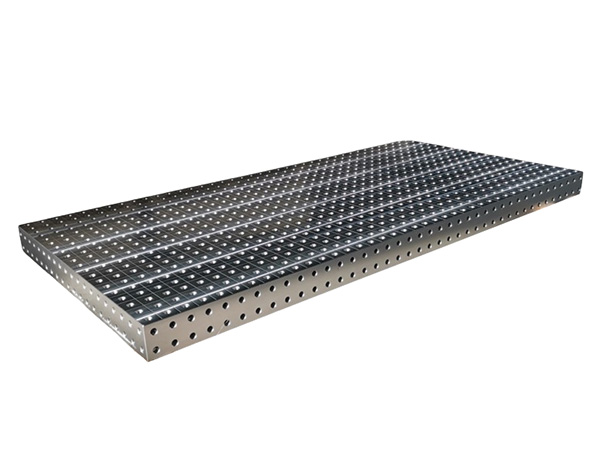

Product classification: According to the hole system, it is divided into two series: Φ28 and Φ16. According to the structure, it is divided into two-dimensional flexible combined tooling and three-dimensional flexible combined tooling. According to the material, the tooling platform is divided into steel platform, cast iron platform and composite plate platform;

Technical parameters: The hole spacing of the 28 series tooling platform is 100mm, and the hole spacing of the 16 series tooling platform is 50mm. Corresponding grid lines are engraved on the platforms. According to customer requirements, millimeter scales can be engraved on the two right-angled sides of the platform;

1. Universal 2D and 3D tooling platform (Φ16, Φ28 hole system):

1) Flatness of tooling platform: ≤0.15mm/1000mm, verticality of 3D platform plane and side: ≤0.1mm/1000mm

2) Material of tooling platform: steel (low alloy steel Q345), which undergoes overall stepped heat treatment to eliminate internal stress.

3) Hole distance position tolerance within ±0.05mm

4) The hole spacing of Φ16 series is 50mm, and the hole spacing of Φ28 series is 100mm.

2. Main accessories of tooling fixtures:

1) U-shaped square box, L-shaped square box:

Material: Q345, flatness ≤ 0.1mm/1000mm, verticality ≤ 0.1/200mm, parallelism ≤ 0.10/200mm

2) Support angle iron:

Material: Q345 or HT300, flatness ≤ 0.1mm/m2, verticality ≤ 0.15/200mm, parallelism ≤ 0.10/200mm

3) Positioning parts: Material: Q345, flatness ≤ 0.2mm/m2, verticality ≤ 0.15/200mm, parallelism ≤ 0.20/200mm

4) Angle device: Material: Q345, can accurately position any angle from 0 to 225 degrees according to the scale, and the angle adjustment is accurate to 0.5 degrees.

5) Locking parts: Material: Q345, locking force ≥1.2T, quenching and tempering treatment HRC32~35°; steel ball quenching treatment HRC58~62°

6) Pressing parts: Material: Q345, tempered

Application industries: automobile manufacturing, engineering machinery, shipbuilding, aerospace, rail transit, structural parts welding, sheet metal boxes, bicycle (motorcycle) manufacturing, supporting welding robots or special welding machines, etc.