- 网站导航 -

Address:Home > Products > Welding fixture >

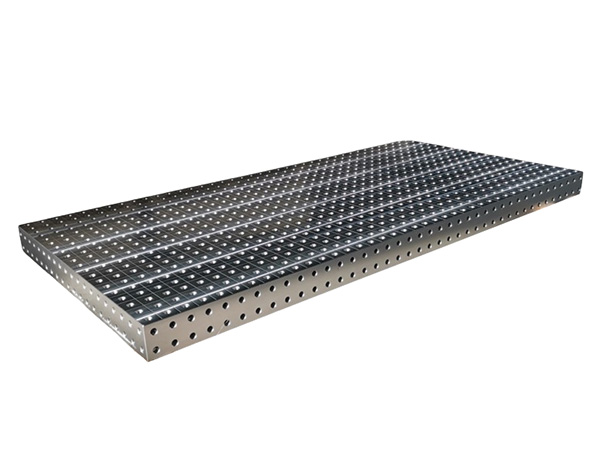

The Welding fixture positioning pin plays a crucial role in constraining the movement of objects, particularly in mechanical equipment where precise two-dimensional positioning is essential.

These pins utilize workpiece holes as reference points to restrict object movement, governing linear motion along the X, Y, and Z axes, as well as rotational freedom around these axes. In mold assemblies comprising multiple parts, these pins ensure accurate alignment between adjacent mold components.

Applications:

When assembling machine bodies from multiple parts, maintaining positional accuracy is critical during processing and assembly. For instance, in a split box assembly consisting of a machine cover and base with precision-bearing holes, strategic placement of two welding fixture positioning pins on the split surface during design ensures precise processing and assembly.

Structural Considerations:

To guarantee post-assembly positional accuracy, cylindrical or conical pins are commonly used for their precise fit, necessitating high standards for pin and pin hole tolerances. Where feasible, pin holes should be designed as through holes to facilitate easier processing of both pins and holes.

Enhance your manufacturing precision with our dependable Welding fixture positioning pins. Engineered for seamless integration and precise alignment, these pins optimize assembly workflows, ensuring consistent performance in complex mechanical setups. Whether in mold fabrication or assembly of intricate machine parts, our solutions deliver reliability and efficiency. Elevate your production standards with our innovative positioning solutions today.